At Gym and Garage Floor Company, we manufacture top-quality rubber mats and flooring in South Africa. Our mats are designed for durability, safety, and eco-friendliness, making them perfect for both indoor and outdoor applications. Whether you need flooring for a gym, garage, workshop, playground, or industrial space, we have the right solution for you.

Our Extensive Range of Rubber Mats

- Gym Mats – Absorb impact and prevent injuries.

- Exercise Equipment Mats – Protect floors from heavy machines.

- Yoga Mats – Non-slip, cushioned surface for comfort.

- Fitness Mats – Designed for various workout routines.

- Dance Mats – Shock-absorbent for dance studios and training centers.

- Martial Arts Mats – Thick, cushioned support for combat sports.

- Workout Mats – Multi-purpose mats for home and commercial gyms.

- Play Mats – Soft and safe for children’s play areas.

- Safety Mats – Anti-fatigue properties for workplace safety.

- Sports Mats – Impact-resistant for athletic activities.

What you need to know about rubber mats

Rubber is a product that has been used in industrial and domestic applications for centuries and it has no substitute in most instances. Most of the rubber products mainly come from India and West African countries.

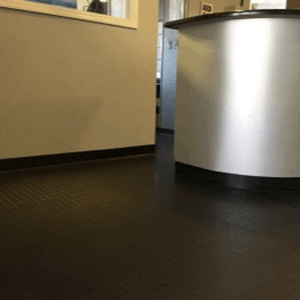

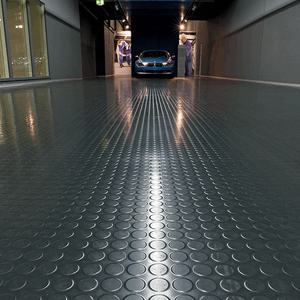

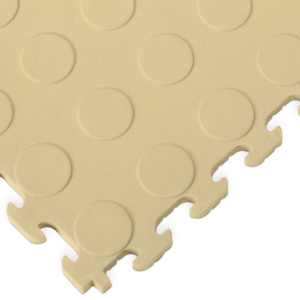

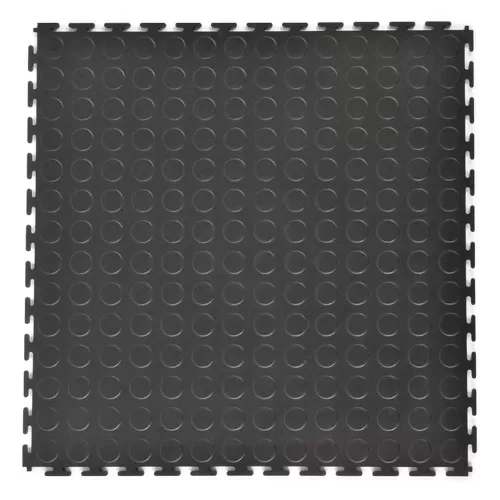

The most popular Rubber Mat for Garage in South Africa are the black medallion or coin-faced mats otherwise known as a black rubber mat.

This is because the Rubber Floor Tiles price for black is relatively cheaper as compared to the colored ones. These rubber mats interlock like a puzzle to make them more durable and easier to install. Coin rubber flooring is the best and most popular form of Rubber Floor Matting.

Why Choose Our Rubber Mats?

- Durable & Long-Lasting – Built for years of heavy use.

- Slip-Resistant – Ensures safety in wet or dry conditions.

- Eco-Friendly – Manufactured from 100% recycled PVC materials.

- Easy Installation – Interlocking system for quick, seamless setup.

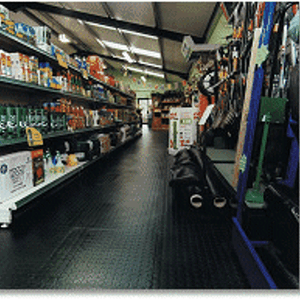

- Versatile Applications – Ideal for gyms, garages, offices, playgrounds, warehouses, and more.

Types of Rubber Mats Available

- Interlocking Rubber Tiles – Easy to install, perfect for modular flooring.

- Rubber Flooring Rolls – Seamless and continuous coverage for large areas.

- Outdoor & Indoor Rubber Mat – Weather-resistant for any environment.

- Rubber Sheeting & Rubber Tiles – Versatile for various flooring applications.

- Gym Rubber Tiles & Mats – Shock-absorbent and durable for gym setups.

- Exercise & Yoga Mats – Comfortable, non-slip surface for fitness routines.

- Martial Arts & Fitness Mats – Thick cushioning to reduce impact and injury.

- Safety & Play Mats – Designed for child safety and workplace protection.

Advantages of Rubber Interlocking Mats

- No Need for Formwork or Scaffolding – Quick and easy installation.

- Fast Setup – Saves time and effort compared to traditional flooring.

- Highly Durable – Withstands heavy use in commercial and industrial spaces.

- Versatile Use – Perfect for gyms, offices, playgrounds, and warehouses.

- Floor Protection – Prevents cracking, absorbs impact, and enhances safety.

Best-Selling Rubber Mats in South Africa

Interlocking Garage Mats (500mmx500mmx5mm)

- Coin-Pattern Design: Classic black finish hides stains, resists oil/spills.

- DIY Installation: Snap tiles together like a puzzle – no tools needed!

- Weight Rating: Withstand vehicles, gym equipment, and workshop tools.

Gym & Fitness Mats

- Shock-Absorbent: Protect joints during workouts (yoga, CrossFit, martial arts).

- Non-Slip Surface: Stay safe during high-intensity training.

- Includes Free Storage Bag: Fold and store effortlessly.

Specialty Mats

- Workshop Safety Mats: Anti-fatigue design for long hours.

- Play Mats: Cushioned for kids’ safety – wipe-clean surfaces.

- Rubber Tiles: Mix colors/styles for custom gym or garage flooring.

Leading rubber mats supplier in South Africa

Our extensive range of rubber tiles includes gym rubber mat, garage rubber mats and workshop rubber mats. Our rubber interlocking mats are of exceptional quality that we give a generous warranty than industry standards. Our rubber mat can be used in any application but are of industrial nature and are able to withstand a great deal of abuse

Properties of rubber

- Highly flexible

- Very higher tensile strength

- Resistant to water and certain chemicals

- Durable with correct application going over 10 years

Rubber Mats vs. Concrete/Epoxy: Why Rubber Wins

Rubber Mats vs. Concrete/Epoxy: Why Rubber Wins

| Feature | Rubber Mats | Concrete/Epoxy |

|---|---|---|

| Cost | R130.30 (budget-friendly) | 2–3x more expensive |

| Installation | DIY in 1 hour | Requires professionals |

| Lifespan | 10+ years | Cracks within 5 years |

| Maintenance | Hose down in minutes | Repolishing/sealing |

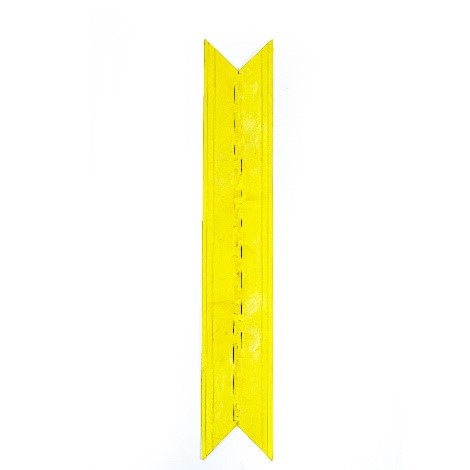

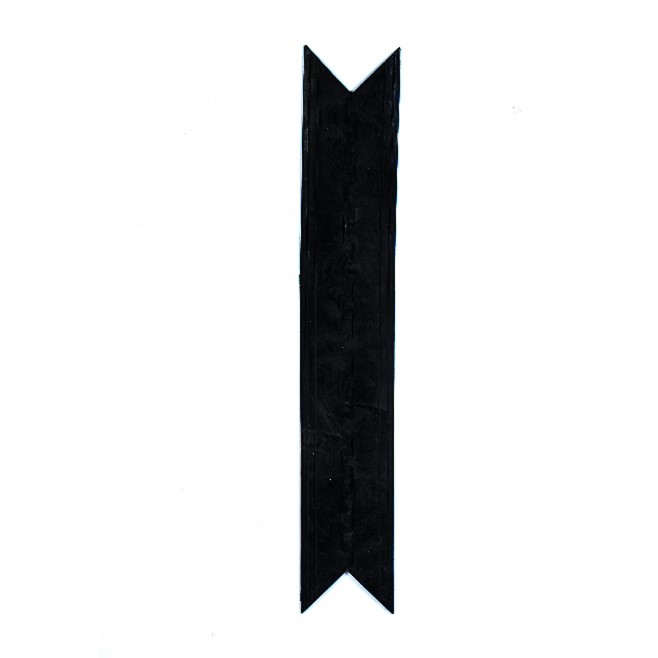

Rubber Mats Edging for Interlocking Tiles

- Smooth Transitions – Reduces tripping hazards and creates a seamless appearance.

- Enhanced Durability – Protects the edges of interlocking mats from wear and tear.

- Easy Installation – Simple snap-on design for a secure fit.

- Custom Fit – Available in various sizes to match your interlocking tiles.

Technical Specifications of rubber Mats

View Our Specifications in Detail

| Product Code | GM-0083 |

| Material Name | High-Grade Recycled PVC |

| Common Name(s) | Garage Floor Mats, Garage Flooring Tiles, Workshop Mats, Industrial Floor Mat, |

| Categories | Garage Matting, Workshop Flooring, Industrial Flooring |

| Thickness (varies) | 5mm, 7mm, 10mm |

| Warranty | 1 Year Limited Warranty |

| Dimensions | 500mm x 500mm per tile |

| Colours | Black, Grey, Blue, Red, Yellow, Beige, Green |

| Shore Hardness | 65A |

| Surface Finish | Textured, non-slip |

| Weight per tile | 1.6kg |

| Working Temperature | -20°C to 70°C |

| Locking System | Interlocking edges |

| Resistance to | Chemicals, Oils, Abrasion09:43 |

| Prices | Start From R130.30 Black |

Faqs and maintenance Tips about Rubber Mats

Maintaining Your Rubber Mat: Tips for Longevity

Cleaning Best Practices

- Daily: Sweep or vacuum.

- Monthly: Wash with mild soap and water.

Avoiding Damage

- Keep away from direct sunlight to prevent cracking.

- Avoid petroleum-based cleaners.

Storage Tips

- Roll mats vertically to prevent creases during storage.

Frequently Asked Questions

- Are rubber tiles or mats safe for use around pets?

Yes! High-quality rubber tiles or mats are non-toxic, chew-resistant, and easy to clean, making them ideal for pet areas. Ensure the mat is labelled “pet-safe” and free from harmful chemicals like phthalates.

- Can rubber mat be customized for unique spaces?

Absolutely! Many brands offer custom-cut rubber mats for irregular spaces, vehicles, or industrial machinery. Provide measurements or templates for a tailored fit.

- How do I remove stains or discoloration from rubber floor mats?

Mix mild soap with warm water and scrub gently. Avoid bleach or abrasive cleaners, as they can damage the surface. For stubborn stains, use a vinegar-water solution.

- Are rubber mats suitable for high-impact gym equipment?

Yes—thick (5mm+) rubber gym mats absorb shock from weights, treadmills, and CrossFit gear. Look for mats with high-density for maximum durability.

- Can rubber tiles trigger allergies?

Rubber tiles or mats are hypoallergenic and resistant to mold/mildew, making them safe for allergy sufferers.

Additional Information About Rubber Interlocking Mats

Rubber Matting and Sheeting

Rubber matting and sheeting are essential for industrial, commercial, and domestic applications.

- Rubber Sheeting Rolls – Provides full coverage for flooring protection and insulation.

- Rubber Matting – Available in different thicknesses, textures, and sizes for various uses.

- Fine Ribbed Rubber Sheeting – Ideal for anti-slip applications in factories, workshops, and garages.

- Checker Plate Rubber Matting – Heavy-duty, high-traction surface for industrial and warehouse settings.

- Oil-Resistant Rubber Sheeting – Designed for automotive, industrial, and chemical environments.

- Neoprene Rubber Sheeting – Suitable for outdoor and high-temperature applications.

Why Buy from Gym and Garage Floor Company?

- Industry-Leading Warranty – Better coverage than standard warranties.

- Premium Quality Materials – Built for high-performance and longevity.

- Expert Customer Support – Professional assistance with product selection and installation.

Upgrade your space with high-quality rubber mats today! Order now for only R130.30 per mat.

For installation guides and product details, contact us now!